Stratasys and MakerBot Merger

Stratasys will purchase MakerBot for a $403 million stock deal. MakerBot was exploring another round of financing to fund expansion, but recent industry suspicions pointed toward a merger deal. MakerBot will continue to independently produce products after the merger.

By partnering with Stratasys, MakerBot will have access to the resources and distribution network Stratasys has built. The acquisition fills out the product line of Stratasys with more focus on the consumer end. Competitor 3D Systems (DDD) offers the Cube 3D printer, which competes directly with MakerBot.

MakerBot has been criticized for poor management by employees, as evidenced by their reviews on glassdoor. As Stratasys has a more balanced culture, perhaps this acquisition will remedy some of the problems within the MakerBot culture. As MakerBot has grown, they have lacked some of the structure and management needed to support larger scale.

The MakerBot acquisition infuses Stratasys with a huge number of hobbyists and small businesses using MakerBot machines. The crown jewel of the purchase is Thingiverse. With over 100 thousand items ready for 3d printing, Thingiverse is the first place many 3d printing enthusiasts check for 3d models. Content is the next big problem for the 3d printing companies. The social network of people with 3d printers and the data about who prints which models with what machines is extremely valuable to Stratasys.

The bump in the stock price of Stratasys indicates investors agree that this merger creates a stronger company than Stratasys or MakerBot alone. We’re looking forward to see what the future brings for the new Stratasys.

How to Measure How Much Filament is Left in a Spool

If you run out of filament midway through a 3d print, it can be hard to recover the print. If you’re not watching the print job closely, you can even damage your 3d printer. To make sure you have enough filament for the job, here’s a quick way to measure how much is left.

If you always use the same filament, take an empty spool and weigh it in grams. Then weigh the new spool, or spool you have running into your 3d printer and subtract. The result is the weight of how much filament you have left. If you don’t have any empties, you can measure before starting the reel, and then assume that if you bought a standard 1kg spool, the spool weight is whatever is over the 1kg.

How to convert the weight of your filament to the more standard cubic centimeters that is shown in most 3d printing hosts? If you’re using PLA, divide the weight by the standard density of 1.25. If you’re using ABS, divide the weight by the density 1.06. Your particular filament might be lower or higher density, so try to find the data sheet from the manufacturer. Otherwise, these should be safe estimates. For example, for 500g of PLA:

500g / 1.25 g per cubic cm = 400 cubic centimeters of PLA left

Then, because your printer might overextrude, or your density might be off, you should always make sure you have a margin of error between what your print requires and the amount of filament you have calculated. If it’s close, make sure to monitor the print so you can replace the reel with a new one if it runs low.

Halfway through a reel and you didn’t weigh your full spool? Try to find your filament on amazon. Listed below the description is an “Item Weight” and a “Shipping Weight”. The difference between the two is the weight of the empty spool plus any packaging. So you should always end up with a filament weight slightly over the actual weight, which means you won’t overestimate and have a failure towards the end of a print.

Knowing how much filament you have left will give you the information you need to plan out a successful 3d print. Standard 3d printer host software tells you how much filament a model will require. You can use that to guide whether you need to watch the print actively, intervene at a certain time to switch out reels, or be confident knowing that your print will have enough filament for the full print.

3d Printing Saves a Baby’s Life

When a six week baby’s windpipe collapsed, blocking airflow to his lungs, doctors at the University of Michigan decided to try a new technique using 3d printing to save his life. Glenn Green, M.D. scanned the baby’s windpipe with a CT scan, generating a 3d model from the scan. With the help of another doctor, the two designed a custom fit tracheal splint that could hold open the collapsed airway.

The custom splint was 3d printed with a biopolymer called polycaprolactone, which absorbs slowly into the body. The doctors sewed the splint around the baby’s airway, where it provided the structure the baby’s lung needed. Almost immediately the baby began breathing normally, and has been healthy for the year since the procedure.

The doctors hope the scan-based design and 3d printing with biomaterials can be adapted to many other problem areas. They’ve already used it to build ear, nose, and bone structures in experimental models to show that the technique can help benefit other patients with similar issues.

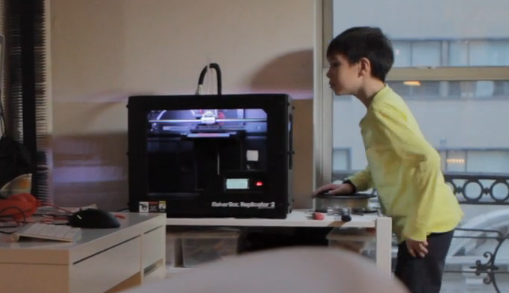

Why Buy A 3d Printer: A Child’s Perspective

On the Media posted a video about a 3d printing from an 11 year old’s perspective. 3d printing has recently become synonymous with controversy about gun control, but this video reminds viewers that most 3d printers are used for experimenting and personalized projects. The video also includes parts of the powerpoint presentation the 11 year old inventor created to convince his parents to purchase a 3d printer.

Defcad Fails Spectacularly

Defcad, the 3d file repository started by Defense Distributed to distribute their 3d printable gun files is shut down. Defense Distributed test fired a low quality zip gun earlier this week that was mostly 3d printed. The 3d files were released publicly on their “censorship free” 3d repository. In response, the U.S. Department of Defense Trade Controls has taken control of defcad and removed all links to the 3d files.

Defense Distributed billed defcad as a “unblockable open-source search engine for 3D parts”, and through crowdfunding raised $75,000 in donations. While the weapon design files are still available on github and The Pirate Bay and have been downloaded hundreds of thousands of times, the defcad website has no 3d files currently available. What could they have done differently?

More Printable Model Databases Launch

After the launch of 3DLT last week, two more sites selling 3D models have launched. Forme It offers printable high-resolution models, and 3d Burrito offers an assortment of models. Since the overhead of selling digital items is extremely low, we can expect to see many more of these 3d model sites over time. Here’s a quick rundown about the two new sites, and the future of model sites as we see it.

Forme It consists primarily of many models of objects that have been scanned with a 3d scanner. The scans have been cleaned up to give high quality 3d models. Not all models are printable, some are just raw meshes targeted at 3d creators instead of beginners to 3d printing just looking for models to run through their printers. The Forme It database of skulls, bones, and crystals could provide valuable reference objects for 3d artists. Continue Reading →

3DLT is Not the First 3d Store for Printable Objects

In this age of overhype, the launch of 3DLT at Disrupt was hailed as the launch of the first store for printable objects by TechCrunch. Many blogs and a few news organizations repeated their claim without checking it. But anyone that’s actually involved in 3d printing knows there are already many stores and repositories for objects that are printable.

The kind of marketing hype 3DLT is inspiring is useful for attracting eyes to their business. But it is disinformation that makes the 3d printing ecosystem appear less developed than it really is. A seemingly generic web store with less than 150 models is not disruptive. Turbosquid has 2,500 models available as printable stl files. Thingiverse has over 50,000 models available for free. Many better resources already exist for free and paid 3d models for 3d printing. If 3DLT really wants to disrupt, they need an actually disruptive idea.

Full Color PLA Printer – BotObjects

While it sounds like vaporware, BotObjects claims to have the first full color PLA 3d printer. The ProDesk3D will use a five cartridge system that blends filament in the correct proportions to print in full color. The correct proportion of each color will be blended just as in an inkjet printer, then extruded to create the print. The case of the ProDesk3D is anodized aluminum with orange touches echoing the minimal design of the Form1 3d printer.

The ProDesk3D also reserves an extra extruder for PVA to allow it to print support material dissolvable in water. They also claim the print bed calibrates itself on startup, and that it prints at 25 micron layer heights. No pricing details are yet available, but the features would make the ProDesk3D a premium level printer. Since the ProDesk3D uses a proprietary cartridge system, they may price the printer lower while charging more for filament.

If the ProDesk3D makes it to market in June as expected, it would be the new state of the art machine with the features it claims. But without pictures of actual prints or more specifications, the ProDesk3D is just hype at the moment.

3d Printed Custom Surfboards

Made Boards is creating the first 3d printed custom surfboards based on your body and ride style. They collect data about your weight, style, and water conditions you typically ride on. Then they use similar techniques to hand-crafted boards to create the perfect board for you. Surfboards, paddle boards, and sailboards can all be made with the technique.

All boards are currently printed on Stratasys 3d printers. What normally would be hand carved from styrofoam, creating lots of waste styrofoam, is now 3d printed. They take the blanks and wrap them in bamboo, then seal the frame in fiberglass to finish the board. The shape of the board reflects the personal style of the rider.

The flexibility of 3d printing allows Make Boards to spend time on the finishing touches of the boards, while keeping environmental impact to a minimum. They plan to launch a Kickstarter project this May to ramp up production. What other sports equipment will 3d printing customize next?