How To Automatically Detect Filament Jams

Some new 3d printers have complex systems that allow them to detect filament feed jams. If your settings aren’t quite right, or your bed isn’t level, or you don’t use high quality filament, a jammed filament will result in your 3d printer making air prints, where the print head keeps moving, but doesn’t extrude any plastic. Long prints can be extremely frustrating when you check in on them, they have ended many layers before they should. If you have a 3d printer without filament feed sensors, here’s how to make your own homemade system to alert you when your filament jams.

All you need is a good webcam and some white packing tape or a white out pen. The main idea is to have your computer see when your filament reels stop spinning. Some 3d printers do this with sensors, but since most don’t have these complicated and expensive sensors yet, we’re going to do it optically.

Use the tape or white-out on the side of your reel of filament to make strips like spokes on a bicycle wheel. If your filament reel is made of black plastic, use white. If it’s made of a white cardboard, you can just use a black marker to draw spokes. The software needs high contrast.

Now you need to install Yawcam, a free webcam streaming software. Follow the instructions to install it on your computer with the webcam attached, and set it up to use your webcam. You don’t need to stream the video for this to work. The webcam should be set up facing your filament reels head on. The spokes of the reel should fill the picture.

Once you see the filament reel, in Yawcam, set up motion detection. Set the sensitivity very high and the tolerance fairly low. You’ll need to adjust these to your lighting levels and how good your webcam is. In this case, we want the alert to happen when motion stops, so click the checkbox to “invert motion detection”. The interval can be as high as 20 seconds (20000 ms), because you don’t want to get an alert when your printer is just doing small details. Put both a sound alert and an email alert. That way, if you’re nearby, you hear a sound right when the filament jam happens, and if you’re away, you get an email. If you use an email to SMS gateway, you can even get a text when your filament jams.

Play with the settings a bit until you’re only getting alerts when your filament actually jams. Now you can wander off while your 3d prints are going for long periods of time and not worry as much about filament jams. If it does jam, just pause the print job, push some more in to get rid of the jam. Make sure your filament isn’t tangled further back too. A nice side effect is that this system detects when your prints stop as well, because your filament will stop then too. With this system, you can get more printing done in the same amount of time, all without wasting your time babysitting your 3d printer.

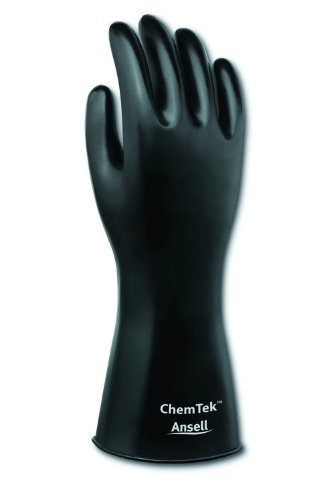

Gloves for Acetone Usage

Acetone is a versatile tool for finishing 3d prints. A vapor bath can smooth layer lines in ABS to make 3d prints have a surface finish like injection molded parts. But exposure to acetone can damage your skin, causing chemical damage that results in dry, cracking, bleeding skin. We’ve seen people hold 3d prints in acetone vapor with their bare hands. How should they be protecting themselves? The best option for safety when using an acetone bath to clean 3d prints is

butyl gloves.

Butyl gloves are specifically designed for use with solvents, and are rated to protect against acetone. They will protect against acetone in liquid and vapor form. So if you’re someone that dips pieces into vapor baths by hand, you should be using a butyl glove to protect yourself. Make sure you pick the one that fits your hand the best, because a good fit means you’ll be more likely to keep using the glove. Butyl gloves tend to last about four years depending on use, so you won’t need to throw them away after each use like latex gloves.

Other gloves that rate highly for use with acetone are natural latex gloves or rubber gloves. Standard nitrile latex gloves do not protect well against acetone. If you’re using the gloves for a vapor bath, you’ll need to find ones with a sleeve long enough to protect your forearms as well. Because they’re specifically designed for solvents, and rate very well against acetone, the top choice for protection against acetone baths are butyl gloves.

Disposing of Limonene

One of the easiest ways to get reliable prints of complex objects is by using HIPS filament. Makerbot dissolvable filament is HIPS. HIPS, a special polystyrene filament, dissolves in the chemical limonene, sometimes known as dilimonene or d-limonene. Limonene dissolves the HIPS scaffolding leaving behind the PLA or ABS structure. Huge overhangs are possible with this method, and cleanup is much easier than manually snipping, clipping, and sanding off scaffolding. What is the best disposal method for Limonene used for 3d printing? Evaporation.

When using Limonene to dissolve HIPS, the usual method is to submerge the object in Limonene so the HIPS melts off the print. After enough uses, the limonene is cloudy with plastic and a layer of sludge builds up at the bottom of the container.

The normal method of disposing Limonene is to dilute it with water then pour it down your drain. If you’re using Limonene to dissolve HIPS, you’ll have plastic residue in the Limonene. HIPS is a version of polystyrene, the same plastic used in packaging materials and styrofoam. If you pour the plastic down your drain, it can build up in your plumbing. Other instructions advise to incinerate Limonene, but when used to dissolve HIPS, you’d also be burning the polystyrene, which gives off toxic fumes.

If you pour your leftover Limonene into a large pan outside, it will slowly evaporate, leaving behind a deposited layer of HIPS. Only do this outside. Limonene vapor can irritate your lungs in a closed space. Limonene is also considered flammable, because it has a low flash point. If you have the limonene evaporating near your 3d printer, there’s a chance the vapor could ignite.

Evaporating the Limonene will take longer, but it is better for your plumbing, the environment, and evaporation is safer than other options.

Microsoft breaks NetFabb cloud repair

A simple tool many 3d printer enthusiasts and professionals use to fix problem models is the cloud 3d model repair by netfabb. It repairs models that the basic version of netfabb can’t, and does it in the cloud, so your computer isn’t slowed down during the complex algorithms. However, Microsoft recently took over the cloud repair site and broke it.

Microsoft announced last June they were partnering with netfabb to simplify 3d printing. The move made sense, as netfabb is a valuable tool that is easy to use. Netfabb giving Microsoft the burden of server maintenance for the cloud tools saves netfabb time and money. But by ceding control, netfabb has allowed Microsoft to tarnish the service quality.

Before, cloud.netfabb would let you upload any stl and just require an email. The new model repair tool forces you to log into a Microsoft account. Microsoft wants users to buy into their software ecosystem just to use the tool. The service is valuable enough that it’s worth giving Microsoft access to your usage data, but it’s a big change from the old netfabb.

Another problem is that Microsoft has made the service brittle. When using chrome and firefox, the two most widely used browsers, the download link doesn’t work if you click any of the about links during the upload or processing then click back. The model shows as processed, but it won’t ever download. There’s a bug in the javascript that prevents the download from starting. It’s great that the new service works with .obj files as well as .stl, but if you can’t download the results, then the service doesn’t work at all.

Microsoft will likely fix the download bug. For now, when you use the cloud repair tool, don’t click anything between uploading the broken file and downloading the fixed file. But this new system shows where Microsoft’s heart is in the 3d printing world. It wants users to use Microsoft products. It forces users to sign up for its Microsoft account to do 3d printing, when a simple email address worked before. If it could, it would make 3d printing Windows exclusive, so that more people would buy Microsoft software and services.

Is ABS Recyclable?

With failed prints, support structures, and prototypes, a 3d printing workspace can generate lots of waste plastic. 3d printing is typically more environmentally friendly, due to less waste material, lower transportation costs, and on-demand prints. But to make your 3d prints greener, how should you handle your extra print material?

ABS plastic, one of the standard materials used in 3d printing, is recyclable. Not every recycling company has the equipment yet to sort and chip ABS. Most metropolitan recycling companies can handle ABS plastic. If your recycling company has single-stream, then you can put support structures and trash prints in with your bottles and cans. If your recycling company supports ABS and requires sorting, your ABS plastic should typically be placed in the bin marked “Other”, so it doesn’t get mixed in with other plastics by mistake.

Another possibility is to recycle your 3d prints into more 3d printing filament with the filabot or filastruder. If you don’t have the money or time to shell out on the system, check with your local maker spaces to see if they have one, or know someone that does.

So if you have a lot of extra ABS you want to dispose, make a quick call to your local recycling company and ask if they allow ABS plastic. Your extra plastic can be recycled into new cell phones, injection molded parts, or if you’re lucky, it may have a second life as lego blocks.

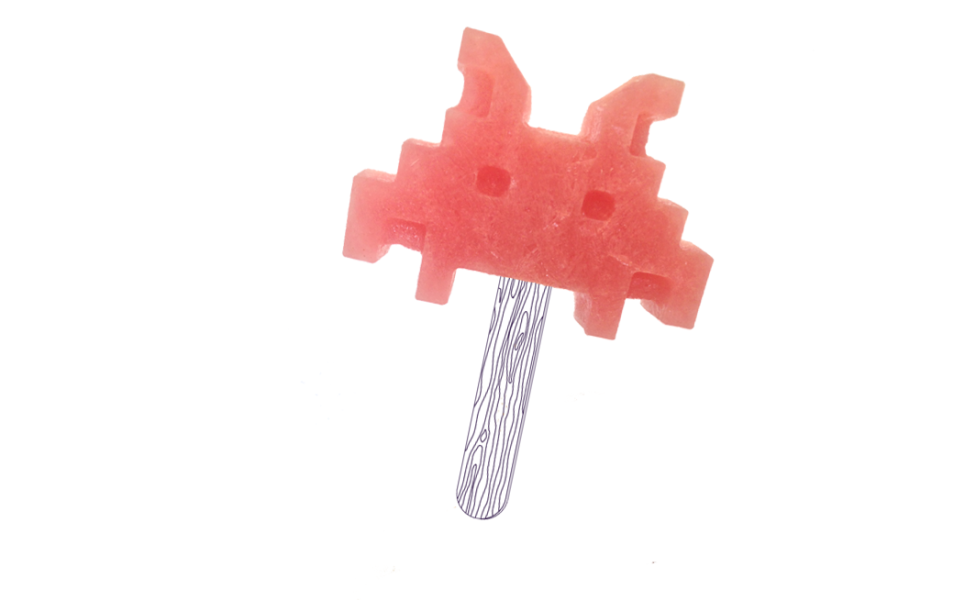

Not 3D Printing: Melt Icepops

Companies trying to capitalize on the cool factor of 3d printing are falsely claiming their products are 3d printers. A new example of this comes from the Melt Icepops, a Netherlands company that makes flavored icepops. As described in various sites, their Icepop Generator “3d printer” makes custom shaped icepops based on 3d models. The problem: what is called a ice 3d printer is a CNC machine.

3d printing is the common name for additive manufacturing. The final print is built layer by layer until the object is completely created. CNC machines drill out a block, subtracting off material until the object is finished. CNC manufacturing is the opposite of 3d printing.

Creating edible ice treats through CNC machining shows innovation, and their process uses similar techniques to 3d printing. Customers could scan their faces then get an edible version of their head. But Melt Icepops is not an example of 3d printing. Mislabeling it as 3d printing is a marketing move just to generate interest in the company.

3D Systems CubePro

3d Systems announced a new entry into the prosumer level 3d printer market with the CubePro. The CubePro supports three colors over a huge build space of 10.8” x 10.45” x 9.5”. The final price is likely to be just under $5000.

image © 3dsystems

This 3d printer is an attempt to play for the dominance of the MakerBot Replicator 2X, which, priced at almost $2,000 less, might be the better option for a prosumer grade printer. The added third color can open up print options unavailable before. However, prints using multiple print heads are only available at lower print resolutions.

For dissolvable supports, the CubePro uses the 3D Systems standard of PLA for support material and ABS for the print. The PLA is dissolved using caustic Sodium Hydroxide in a heated bath. This option requires more equipment and careful technique. Like other 3d Systems printers, you must use their cartridge system for filament. So it forces vendor lock-in for raw materials.

The CubePro is a high priced system clearly targeting the lower pro tier. It’s a clean plug and go system for users who don’t have the time to experiment and just want a system that gives decent prints. If you absolutely need 3 colors, this is the easiest way to get it. If you want a better system with a lower total cost of ownership, the MakerBot Replicator 2X is the clear choice.

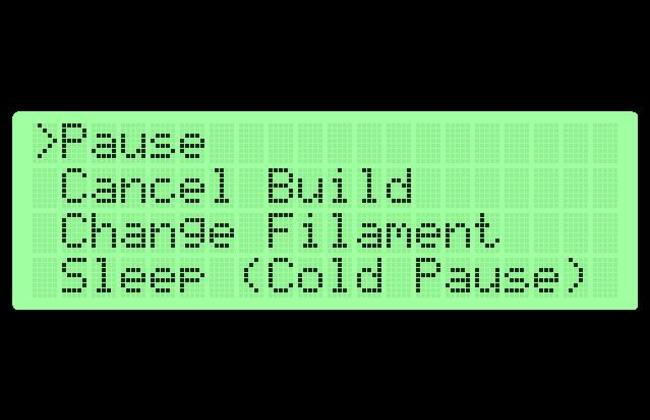

How to Replace MakerBot Filament Mid-Print

MakerBot Replicator lets you switch filament out in mid-print easily with the LCD menus. If your reel of filament is running low, or you’re doing some advanced color switching, here’s how to safely switch the filament.

- Press Filament Change in the menus. Try to press this while your printer is doing infill, so you don’t get a blob on the surface.

- Press Unload. Follow the removal instructions to remove the current color

- Press Load. Follow the loading instructions to insert your new color. If you have a new model with the levers, remember to switch them back so that the motor is driving the filament again.

- Exit the menu, then press Resume Build. The LCD may say “restarting build”, but it is starting up where it left off. The pause/unpause option does not work to resume the build.

This will let you easily switch out filament reels for longer or more colorful prints with less hassle about making sure you have enough. As long as you press Filament Change while the print head is not on important surface detail, the print will resume where it left off. If you switch filament quickly enough, the print won’t cool off too much and the layers will still have good adhesion.

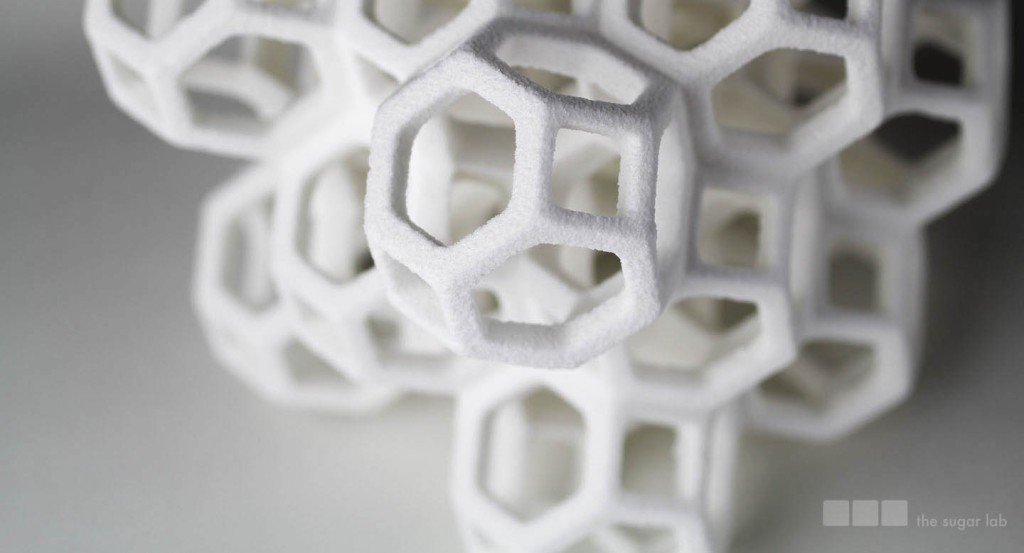

3D Systems Buys The Sugar Lab

3D printing giant 3D Systems announced they have completed purchase of The Sugar Lab, a small startup dedicated to exploring a new way of 3D printing directly in sugar. Their machines allow direct deposit of sugar, building complex objects with ornate geometries. The sugar is printed using the same deposition technology as current FDM, applying one layer at a time. The sugar is held together using a binder that is edible and meets food safety standards.

3D Systems has pursued a strategy of innovation by acquisition, and this is another piece of intellectual property they have added to their stable. The founders of The Sugar Lab have a patent on producing food through 3d printing with the use of edible binders, which was granted earlier this year. This patent is general enough that 3D Systems will be able to be a gatekeeper to 3D printable food systems for the near future. The patent and innovation behind the idea fueled this acquisition.

Problems with Windows 8.1 3D Printing API

Microsoft announced yesterday it will add native 3d printer support to Windows 8.1. The new version of the operating system adds an API to allow developers to use 3d printers as if they were standard 2d printers. System dialogues will provide print previews and send the object to the 3d printer for printing. We took a look at the documentation at the new API and while it makes sense for Microsoft to try to consolidate control, their new workflow both overcomplicates and oversimplifies the process.