Recycled 3d Printer Filament from Scrap Plastic with Filabot

It’s an open secret that 3d printing filament costs much more than it should. $30-$200 for a spool of plastic gives the manufacturers amazing margins, even at the low end. Until the market gets more competition driving the price down, it’s worth investigating Filabot to make your own filament.

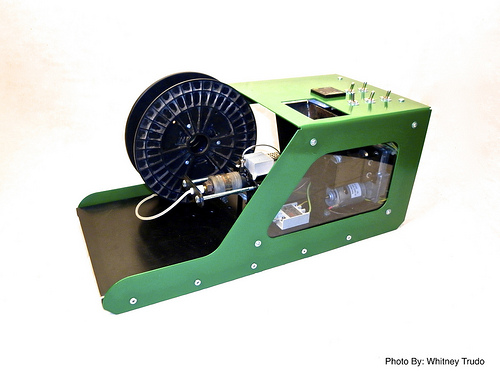

Filabot grinds and melts together scrap plastics to make new 3d printing material. Milk jugs, soda bottles, bad prints, and other clean scrap plastic can be ground into pellets then heated and extruded into filament plastic. Filabot started as a hugely successful Kickstarter project, and they are working on bringing their product to market in 2013.

This plastic won’t be as high quality or as controlled chemically as commercial plastics, but if you’re concerned about the ecological impact of your 3d printing, this provides one way for you to ease your conscience. 3d Systems and Stratasys use custom filament spooling systems that would make using Filabot filament difficult. If too many people figure out how to use cheaper filament purchased elsewhere, they may make the same moves as normal printer ink and use DRM authentication systems to disallow other filaments completely.

We predict we’ll see more certified recycled filaments from larger companies as well as 3d printing takes off. In a landscape with little differences between the filaments offered, going green gives a point of differentiation.