3d Print your Facebook Profile

The creators project teamed up with three noted designers to create 3d printing apps for facebook. The facebook apps use data from your usage of facebook to create a unique 3d printed model that reflects your profile and its connections.

Monster me shows off what kind of profile you have. Crystallized analyzes your connections and networks. It builds a 3d crystal geode out of your networks, showing spikes and distances from your friends. Astroverb shows a kind of zodiac generated from your word usage in your posts.

All three apps use shapeways to print. Monster Me and Crystallized use the full color sandstone option, while Astroverb uses the metallic option. All projects reflect a different view on the personalization of products 3d printing promises. Instead of letting the end user customize his product, these apps automatically generate the final product based on your data. The consumer does not have a hand in the process. Is generative models instead of customized models the answer to the content question?

Obama’s Gun Control and 3d Printing High Capacity Magazines

On Wednesday, President Obama delivered a speech advocating gun control legislation. One provision he endorsed was to limit magazine size to 10 rounds. While adding the provision might limit the spread of larger magazines among hobbyists, 3d printing provides an easy way to bypass any legislation.

Last Sunday, 3d printed firearms company Defense Distributed successfully test fired a 3d printed magazine. The magazine holds 30 rounds, and they fired 85 rounds through it, only stopping when they ran out of ammo. With each test, they iterate their design to make it stronger and fit better, then they share the new design files online, so anyone with a 3d printer can now 3d print the improved magazine.

3d Printed Gummi Bears

The Cad Technology class at the University of Washington had a problem. Who wants to bite off their own head? The class recently experimented with creating gummi versions of themselves with 3d scanning and 3d printing. Using ReconstructMe to scan themselves, the students cleaned the models using Rhino, then made them into a 3d printed mold, which they waxed after printing to make them more food-safe.

They used food-grade silicone with the reverse molds to make the final molds.

After a few false starts, they found that using non-stick spray to coat the interior led to the best gummi humans. They melted gummi bears down and filled the mold with the liquid. After setting overnight, the gummi 3d scan was ready to eat. But the real question is, who wants to bite off their own head?

iMaterialise Working on Dual Material models?

A reporter from People.com.cn recently got a tour behind the scenes at the Brussels factory of Materialise, the parent company of iMaterialise. Among the slideshow showcasing many beautiful 3d prints were two glimpses at a print done with mixed transulucent and opaque material, showing a clear hand with visible skeleton inside.

This comes after Makerbot announced recently the Replicator 2X would have dualstrusion capabilities, letting it print two different materials at once. The Dual version of the Replicator, aptly named the Replicator Dual, supported two print heads as well. A model like the one shown can be made with one of these dual head 3d printers by loading one extruder with transparent filament and the other with a standard white filament.

It’s possible iMaterialize will support mixed transparent and opaque materials for all customers through their website. We contacted iMaterialise, and they’re not supporting dualstrusion or multiple materials yet. But the prototype department at Materialise can. If you’re interested, you might be able to get a custom quote now for a mixed transparency item by emailing prototype @ materialise . be

In the meantime, another option is to find a custom 3d printing service. We’ve heard that SIMT can do multiple material prints with an Object Connex.

Recycled 3d Printer Filament from Scrap Plastic with Filabot

It’s an open secret that 3d printing filament costs much more than it should. $30-$200 for a spool of plastic gives the manufacturers amazing margins, even at the low end. Until the market gets more competition driving the price down, it’s worth investigating Filabot to make your own filament.

Filabot grinds and melts together scrap plastics to make new 3d printing material. Milk jugs, soda bottles, bad prints, and other clean scrap plastic can be ground into pellets then heated and extruded into filament plastic. Filabot started as a hugely successful Kickstarter project, and they are working on bringing their product to market in 2013. Continue Reading →

3d Printed Hearing Aid for the Perfect Fit

Completely personalized products are one of the core reasons 3d printing will take off. A Danish firm has taken that mentality and applied it to hearing aids. A new patient gets their ear scanned by a 3d scanner, which creates a detailed model of the inside of their ear. A custom hearing aid fitting is designed to match the scan, and then each hearing aid is 3d printed. Support structures are removed, and the hearing aid is hand finished to give a high quality surface. The hearing aid technology, called CAMISHA, won the European Inventor Award for 2012.

The new hearing aids match the user better than traditional hearing aids, which are fitted by hand, but can’t match the contours of the inner ear like a 3d scan can. The shell can be smaller than traditional hearing aids, which makes them lighter and less visible. Since a hearing aid is something worn many hours a day, even a slight boost in comfort makes a much better product. The closer fit channels the sound better, so less volume is needed to overcome feedback. 3d scanning and 3d printing combined make the hearing aid more personalized and more usable.

3d Systems Cube Updates for 2013

Say hello to speedy ABS with the new updates to the Cube. 3d systems announced new updates to the machine that bring it more in line with the current market leaders in consumer printers. The updated version prints 1.5 times as fast as the older model, and ABS gives more strength to prints and lets them stand up to more stress.

Even though the bed isn’t heated, the Cube can print ABS through a slight reformulation of the plastic. Combined with some software tweaking, the ABS doesn’t warp as it usually would without a heated bed. Perhaps we’ll see the new formula available for other machines too, letting 3d printers who haven’t upgraded to the heated platform print in ABS as well.

The Cube also has a finer resolution, as they’ve almost doubled the accuracy. Shipping January 21st, the best part of this update is that the price is still $1299.

3d Printing Dinosaur Fossils Instead of Digging

Palaentologist Sergio Azevedo could have dug out the fossil he found by hand, painstakingly chiseling away rock bit by bit, hoping he didn’t accidentally shatter a dinosaur tooth with one misstep. Instead, he 3d printed the bones. He used a portable CT scanner to find the size of the fossil still in the ground, and cut a block around it. They moved the entire block to their lab at the National Museum of Brazil, where they used a high resolution scanner to 3d scan the interior. A bit of cleanup later, and they had a model they 3d printed in resin.

3d printing technology will allow classrooms to be able to have accurate models of fossils. Museums can 3d print replicas of artifacts that visitors could then touch and handle, making exhibits more interactive. And laser scanners are now used to record surface data of fossils before excavation, because they provide more data than photos alone.

MakerBot Replicator 2X

At CES, MakerBot announced their newest model 3d printer, the MakerBot Replicator 2x. This new model increases the build volume from 410 cubic cm, and uses a sturdier, stronger ABS plastic for its extruder. It can deposit in layers up to 100 microns (0.1 mm), so it has roughly the same resolution as the MakerBot Replicator 2. What the price of $2,799 gets you for the extra $600 over the Replicator 2 is the ability to make larger prints more accurately than before, and an extra extruder so you can make objects in two colors printed together.

According to MakerBot, there is no upgrade path planned for the Replicator 2 to Replicator 2X, so don’t expect to see retrofitted multiple prints out of a Replicator 2. This is a bleeding edge printer, but hopefully with the build quality we’ve seen from past MakerBot 3d printers.

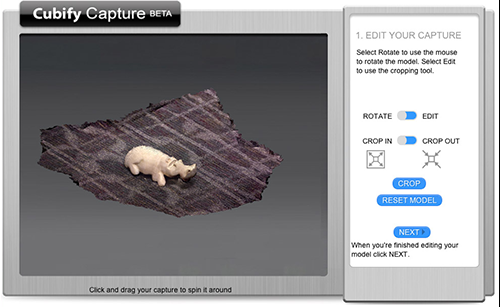

Photos to 3d Models with Cubify Capture

3d Systems is challenging Autodesk’s 123d Capture tool with their new Cubify Capture. The website allows you to upload a set of images, and the server will generate a 3d model from the images. As we said in the 123D Capture review, you’ll have to control how you take your photos carefully to get a good model from them.

The process is very similar to 123D Catch, and the results are similar. Take 30-50 images all around the object you want to digitize, and after upload, Cubify Capture will stitch them together. However, Cubify seems more optimized for 3d printing, and in our testing, generates more solid models. We used similar services from Hypr3d, a company recently acquired by 3d Systems, and it seems likely the technology has been influenced by the recent roll-in.

One of our testers could not create an account with Cubify, and another said the upload stalled. The new features seem to be slightly buggy, but given 3d Systems, we’d expect them to be cleaned up soon.